Hey there, Joey!

Design through empathy. Build through precision. Scale through strategy. My work lives at the intersection of equity, engineering, and strategy — where inclusion drives innovation.

7D Technologies

See more →Active Startup

Present.png)

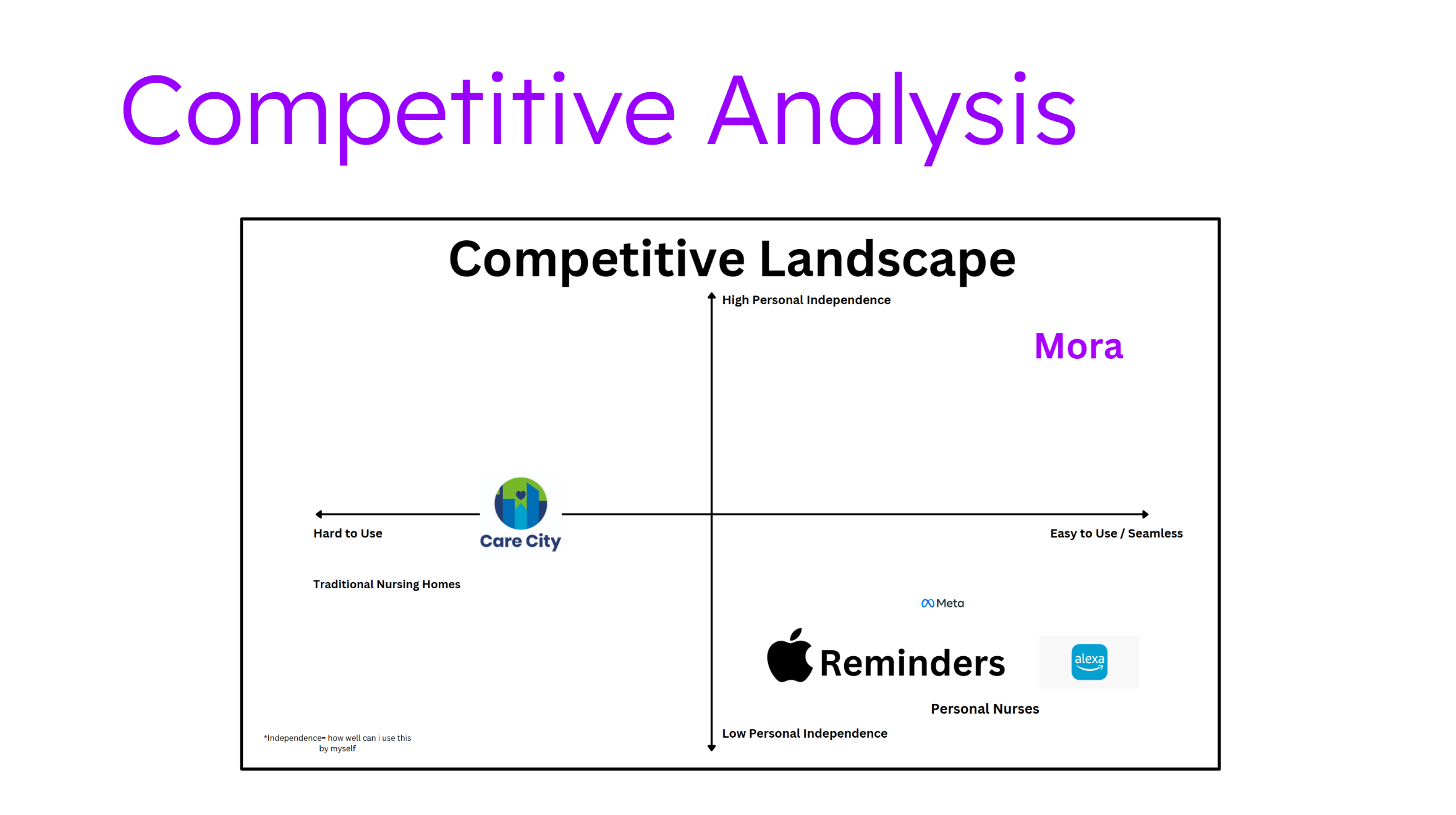

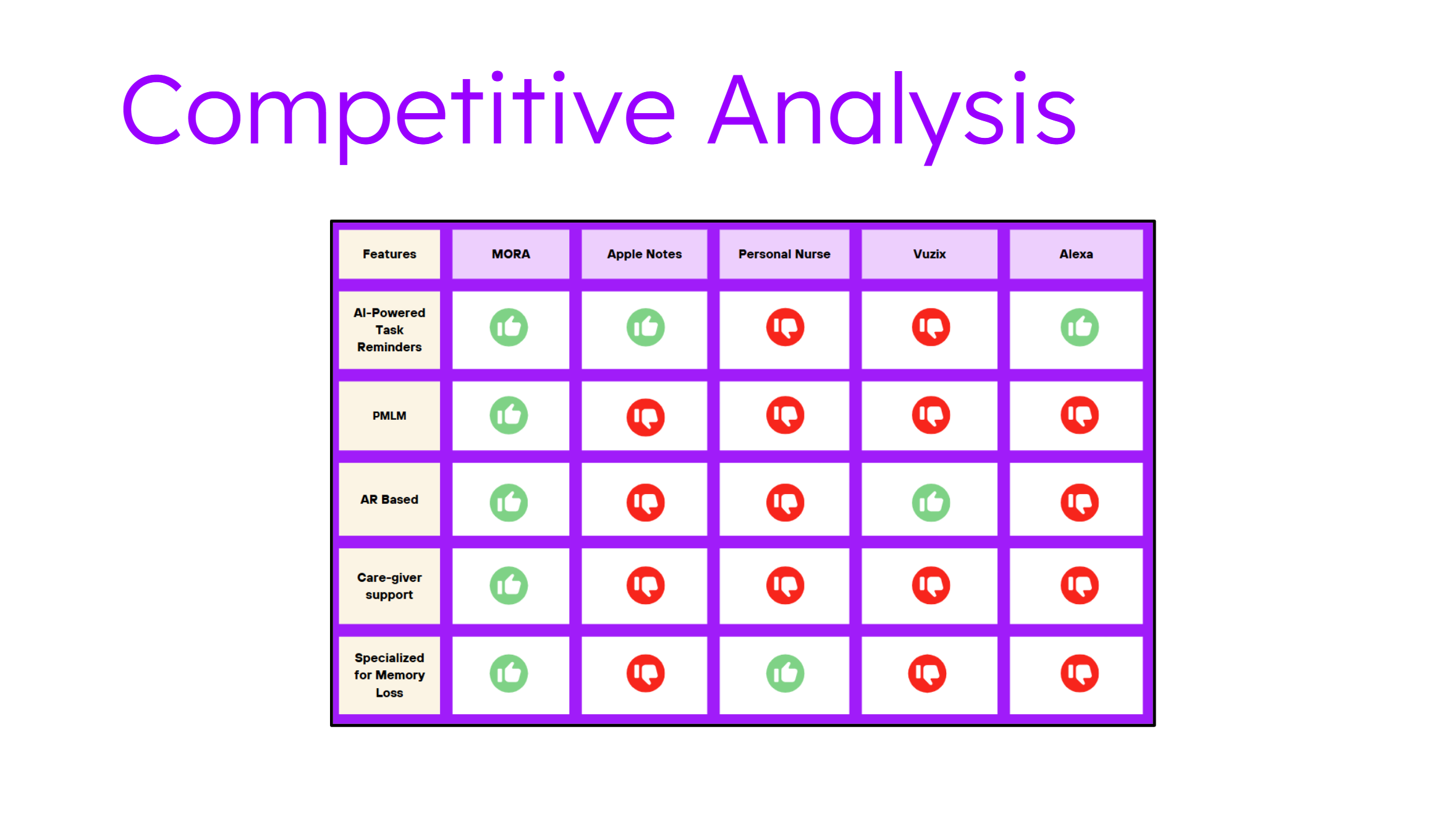

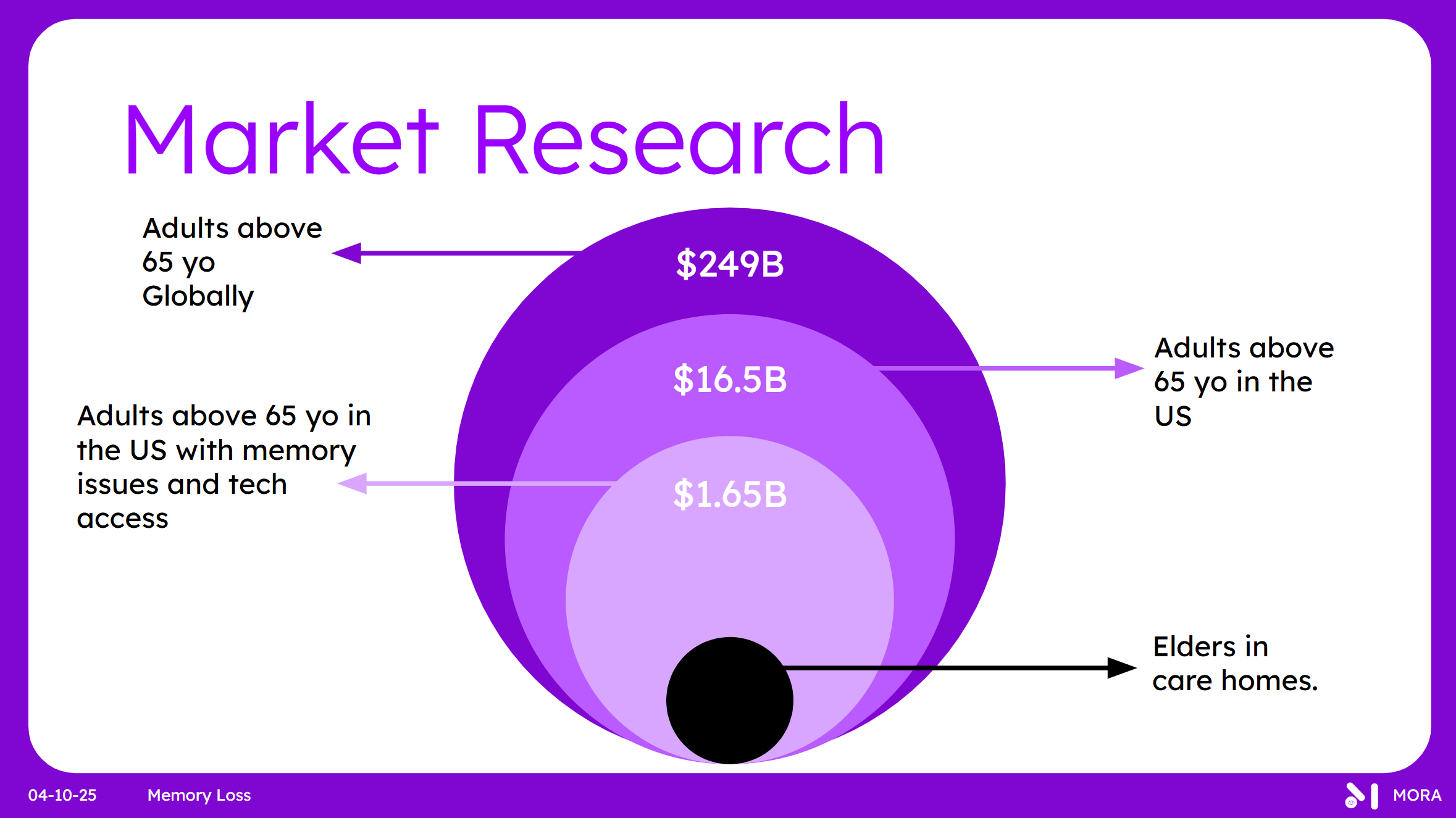

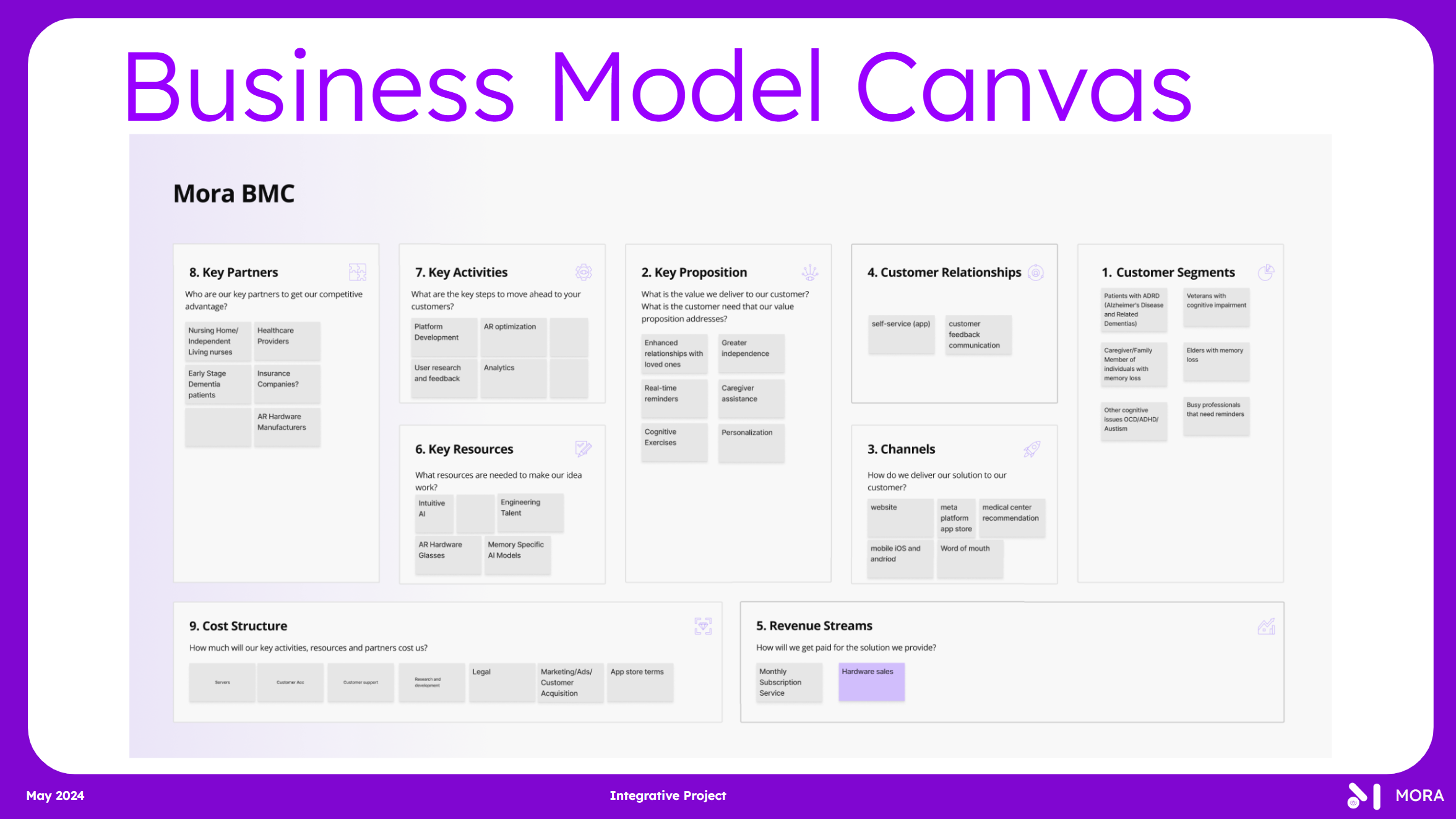

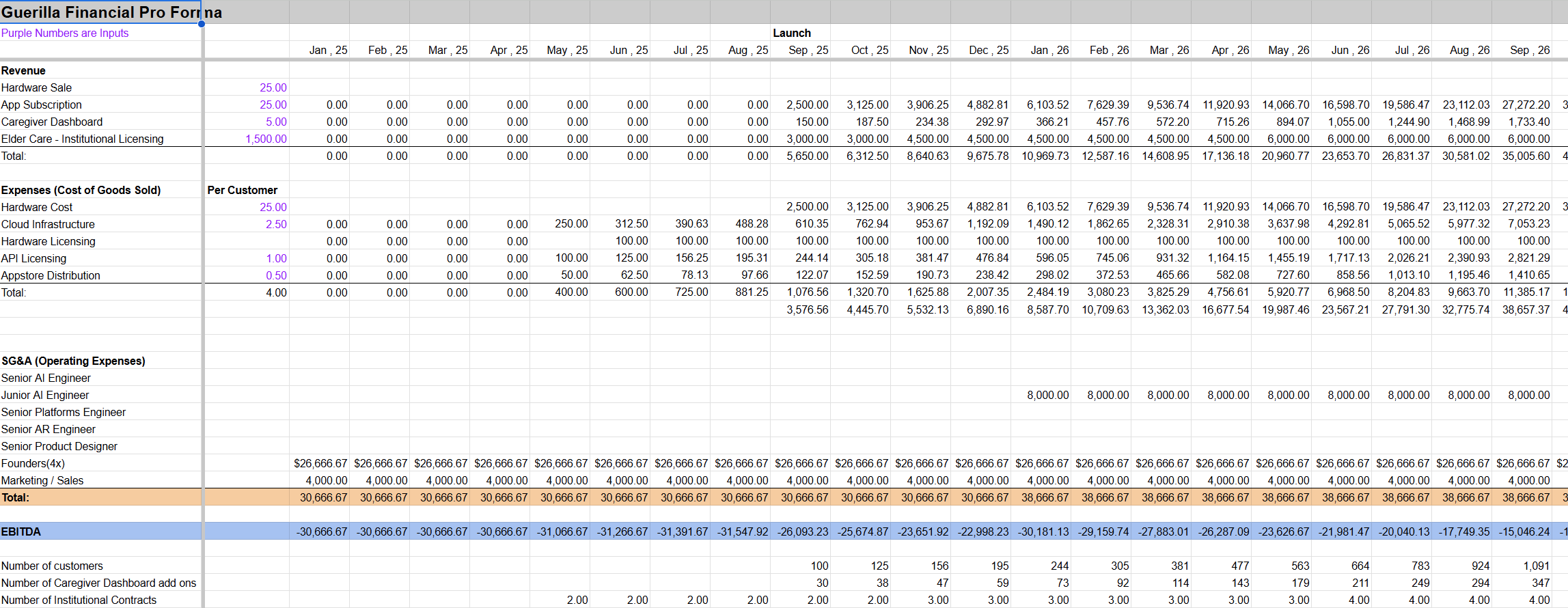

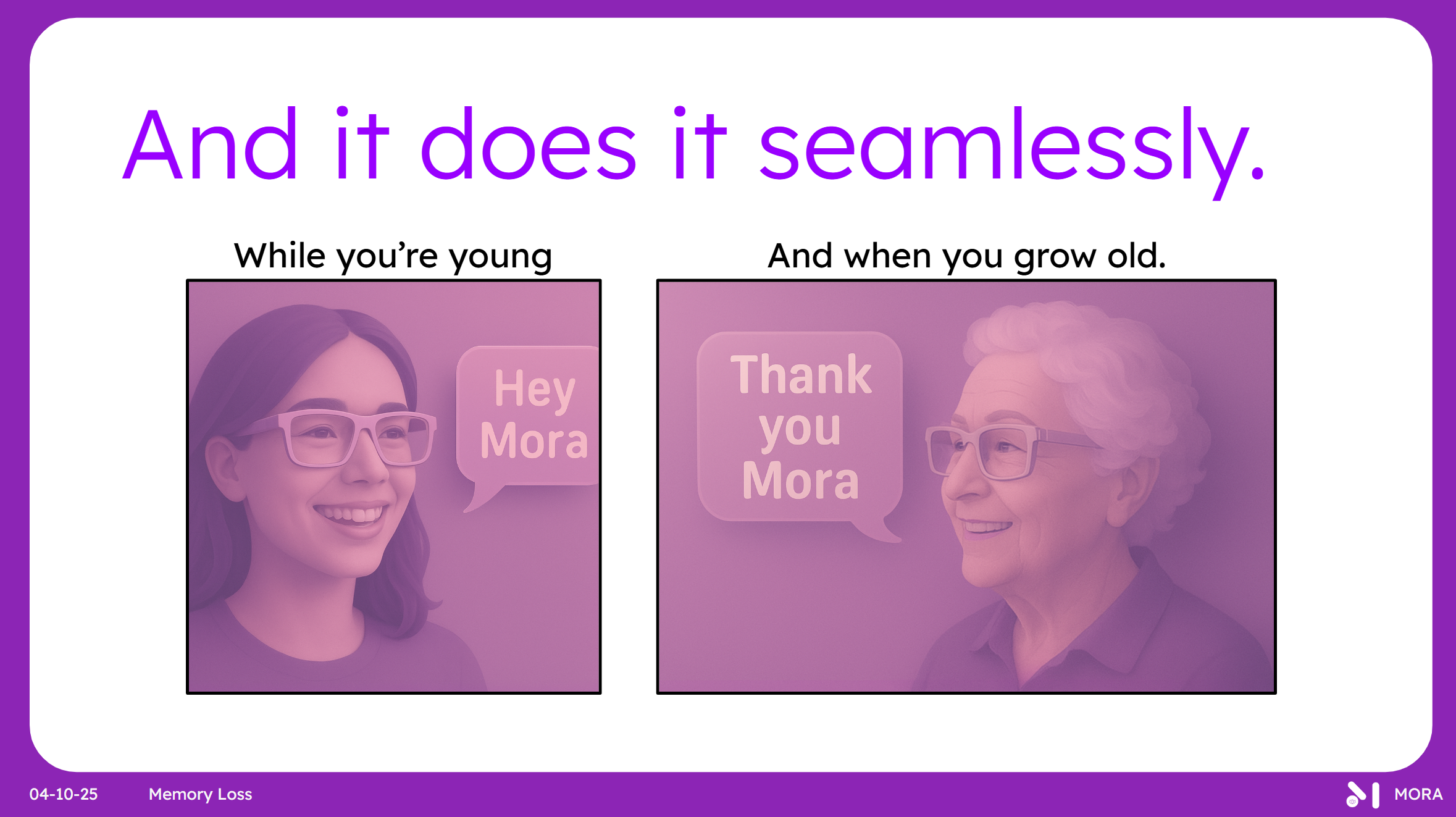

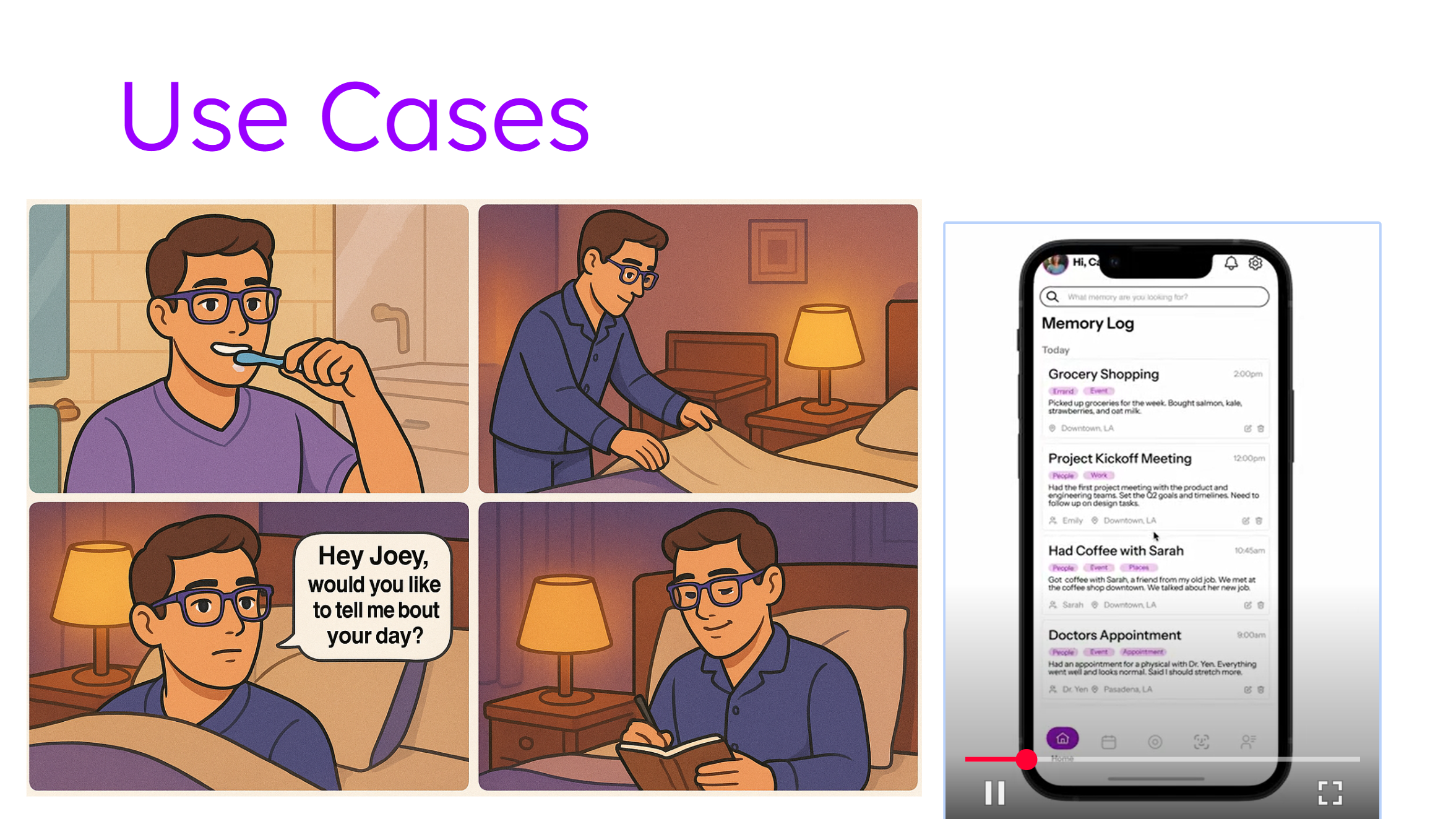

Mora

Case Study →Impact and Strategy Project

2025

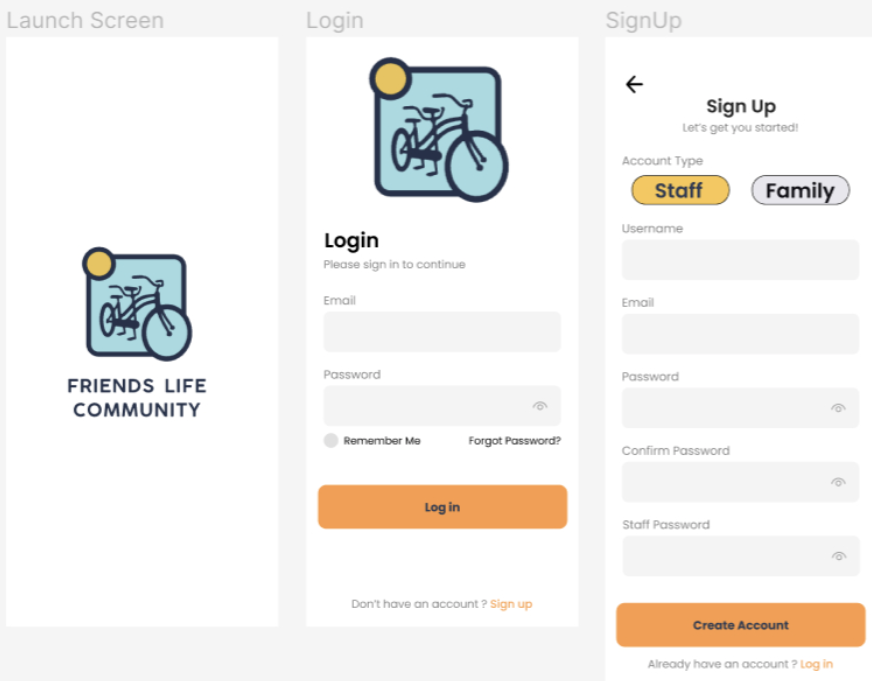

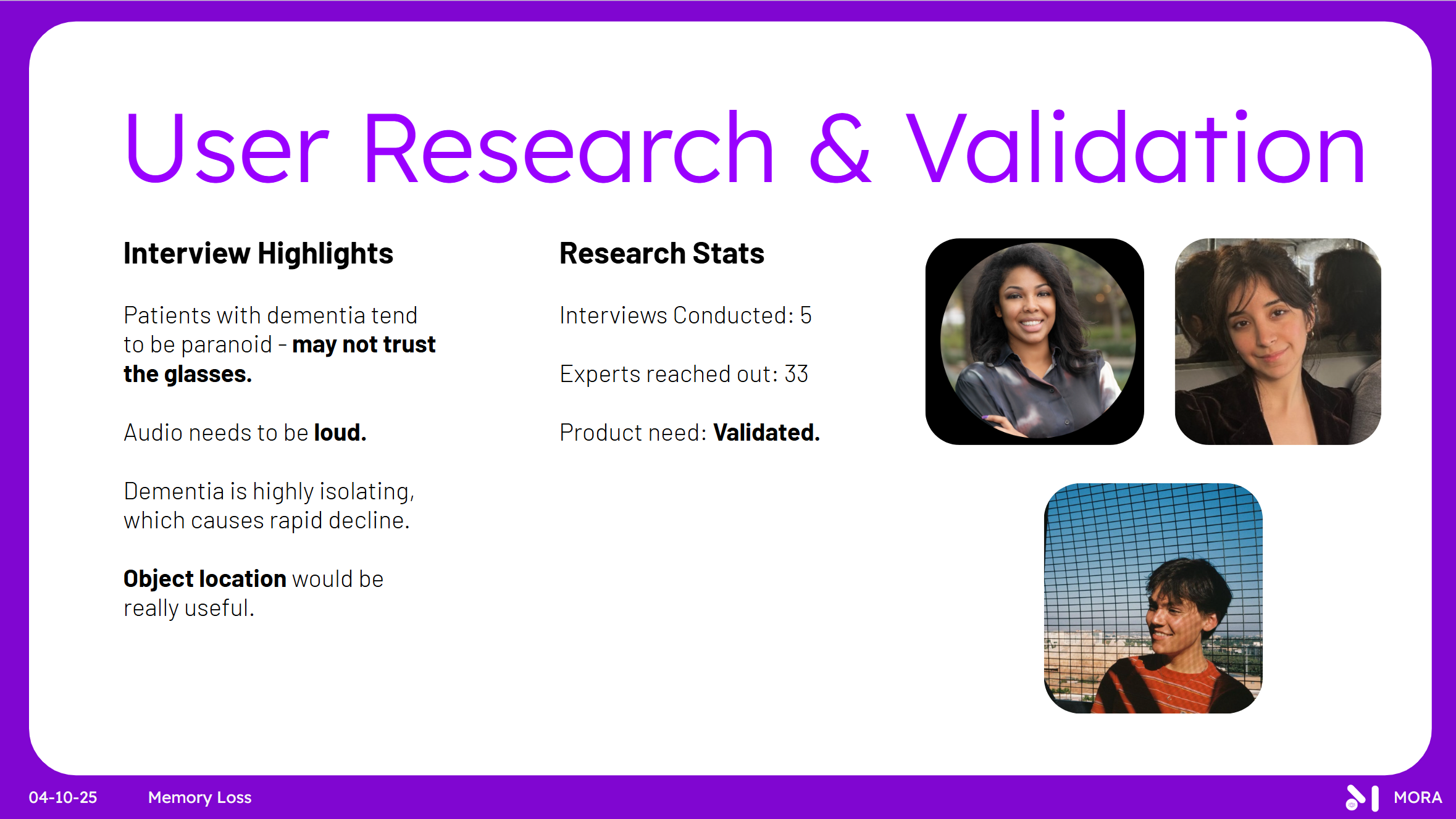

Friends++

Impact and Strategy Project

2023

An Other World

Venture Strategy Project

2025

Gumps

Case Study →Product Design Project

2024

Kokoro

Futures Design Project

2024

Fishing for Futures

Impact Design Project

2024

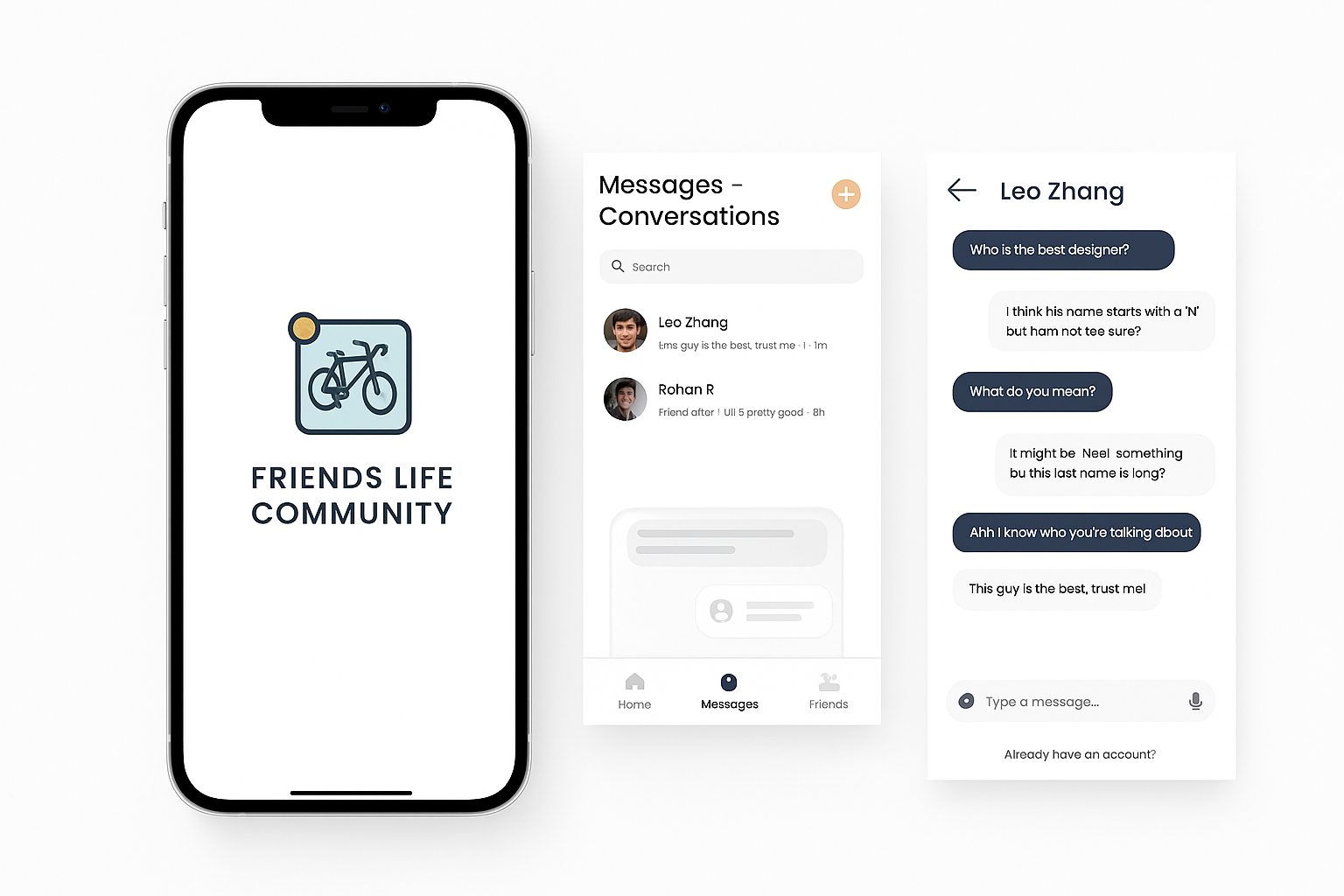

Cultural Nutrition Toolkit

Inclusive Design Project

2025

Polyspace

FuturesDesign Project

2025

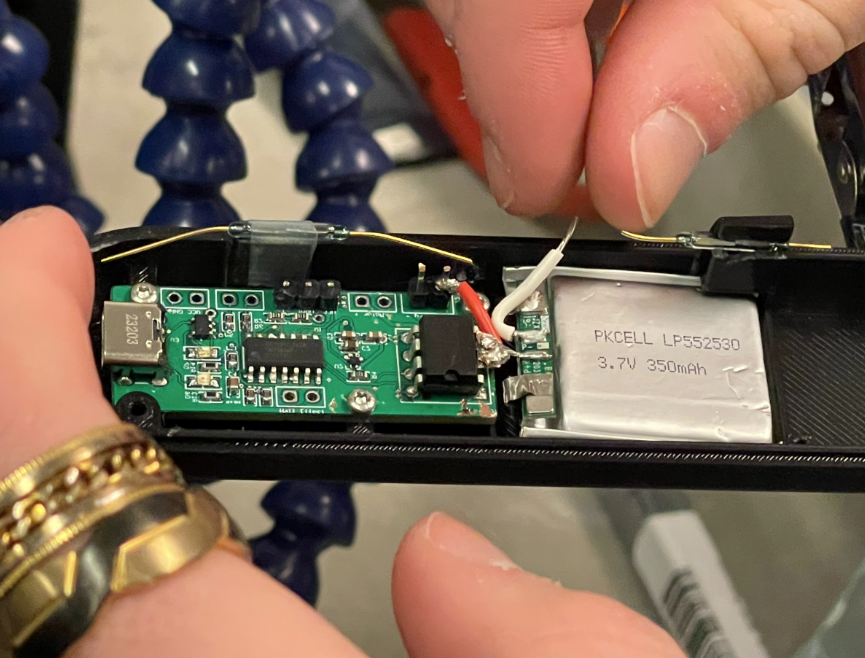

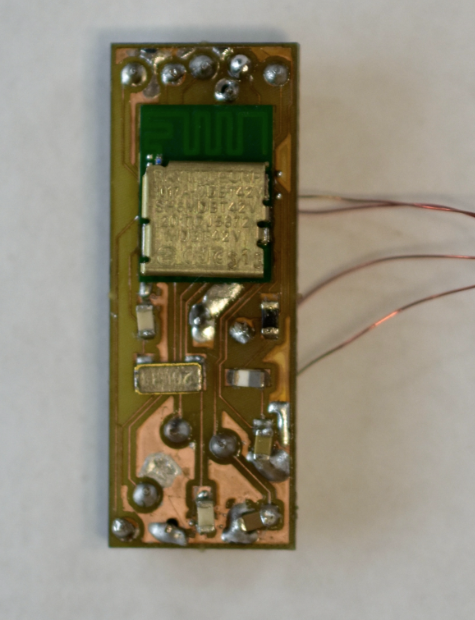

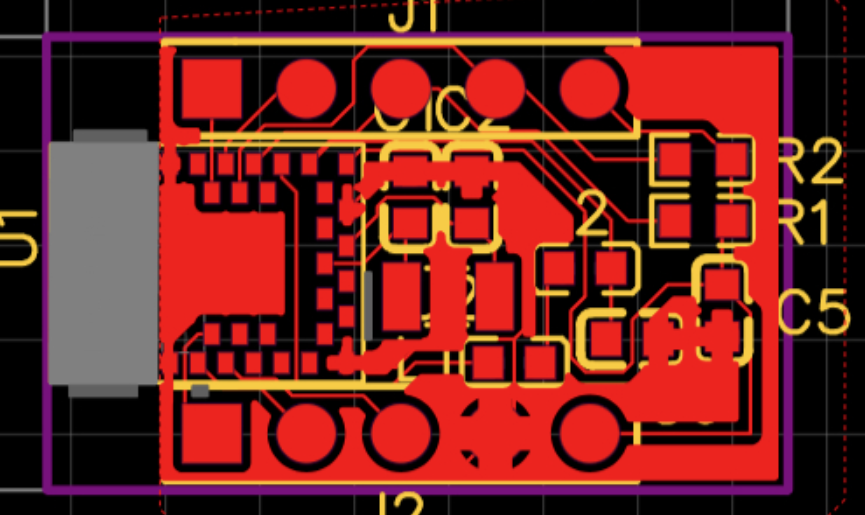

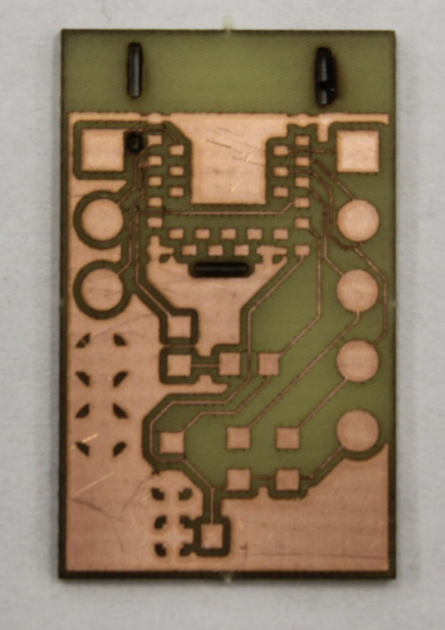

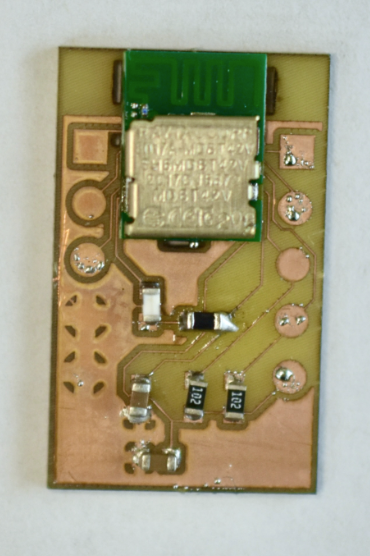

EasyButton

Firmware Engineering Project

2024

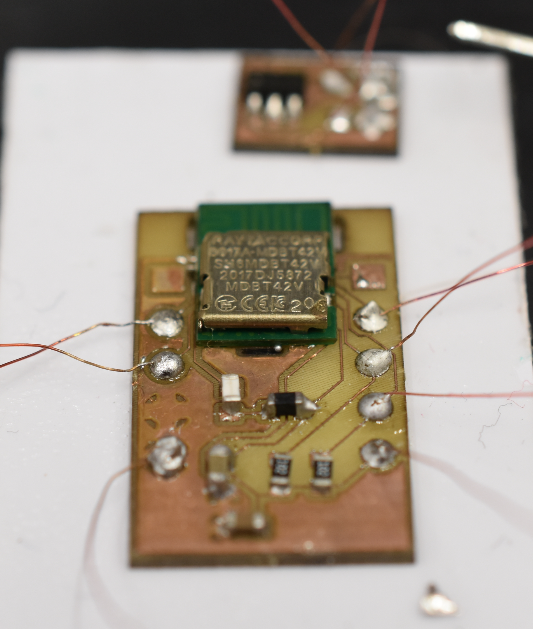

Nanoscale Medical Robotics

Case Study →Published Engineering Research

2024

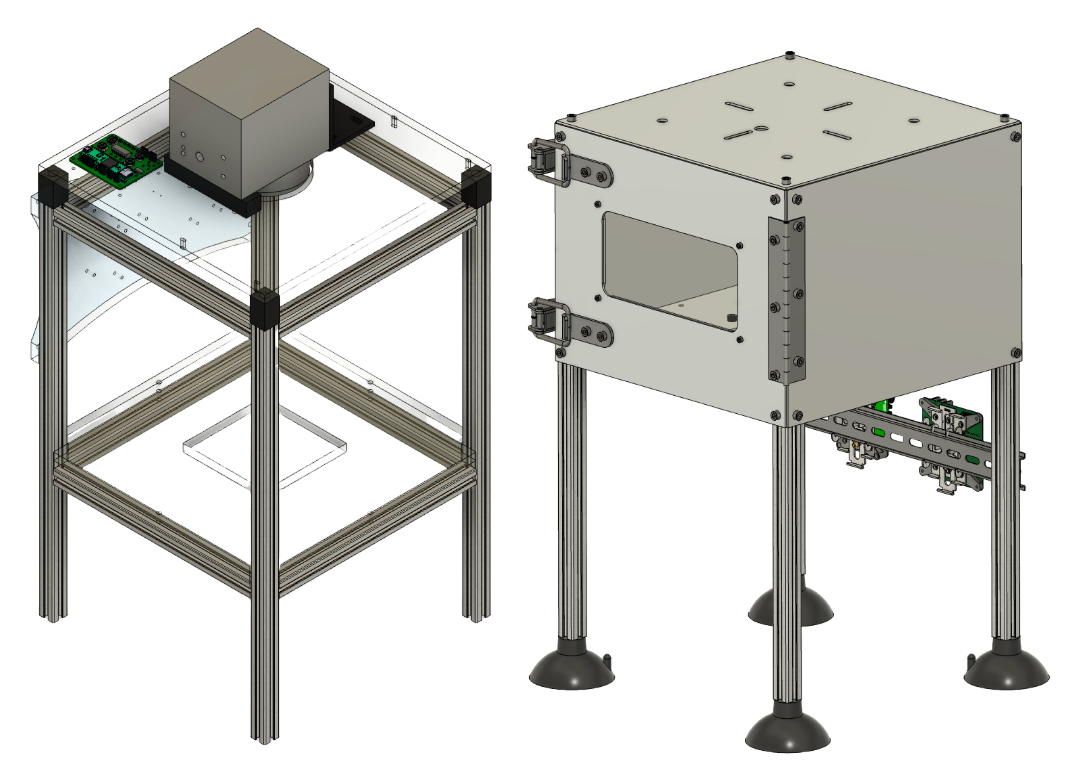

3D Bone Printing

Case Study →Senior Engineering Project

2024

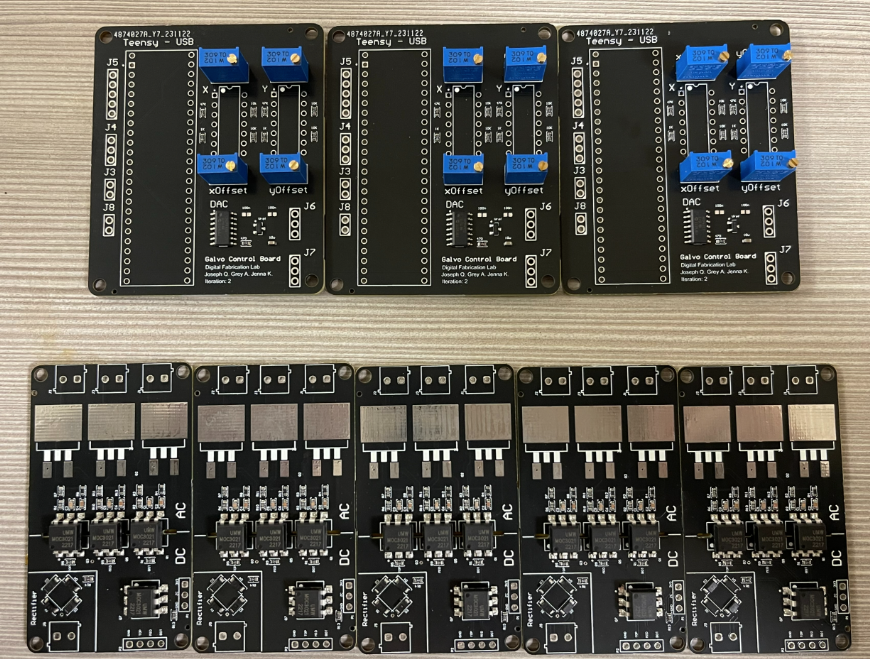

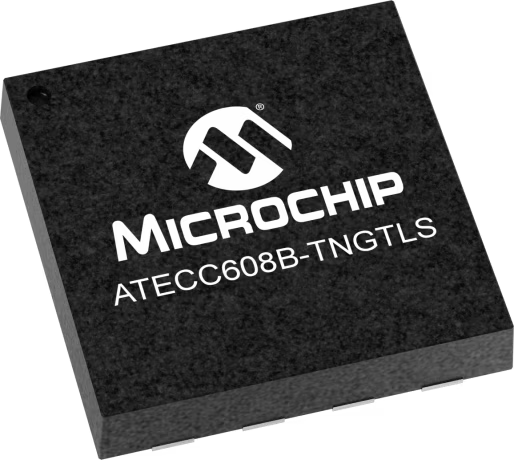

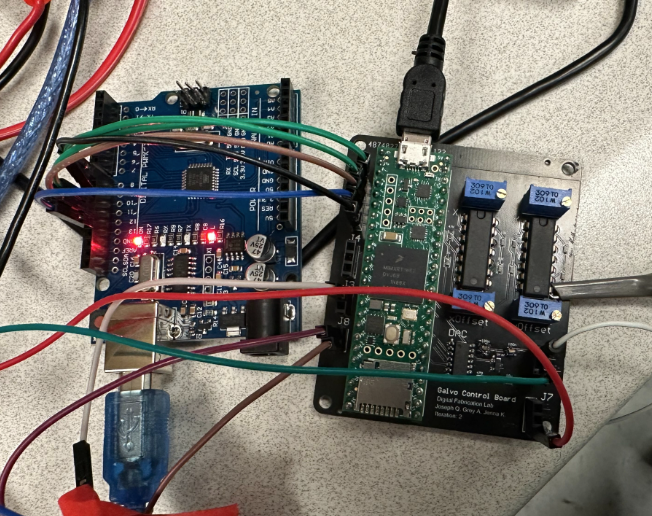

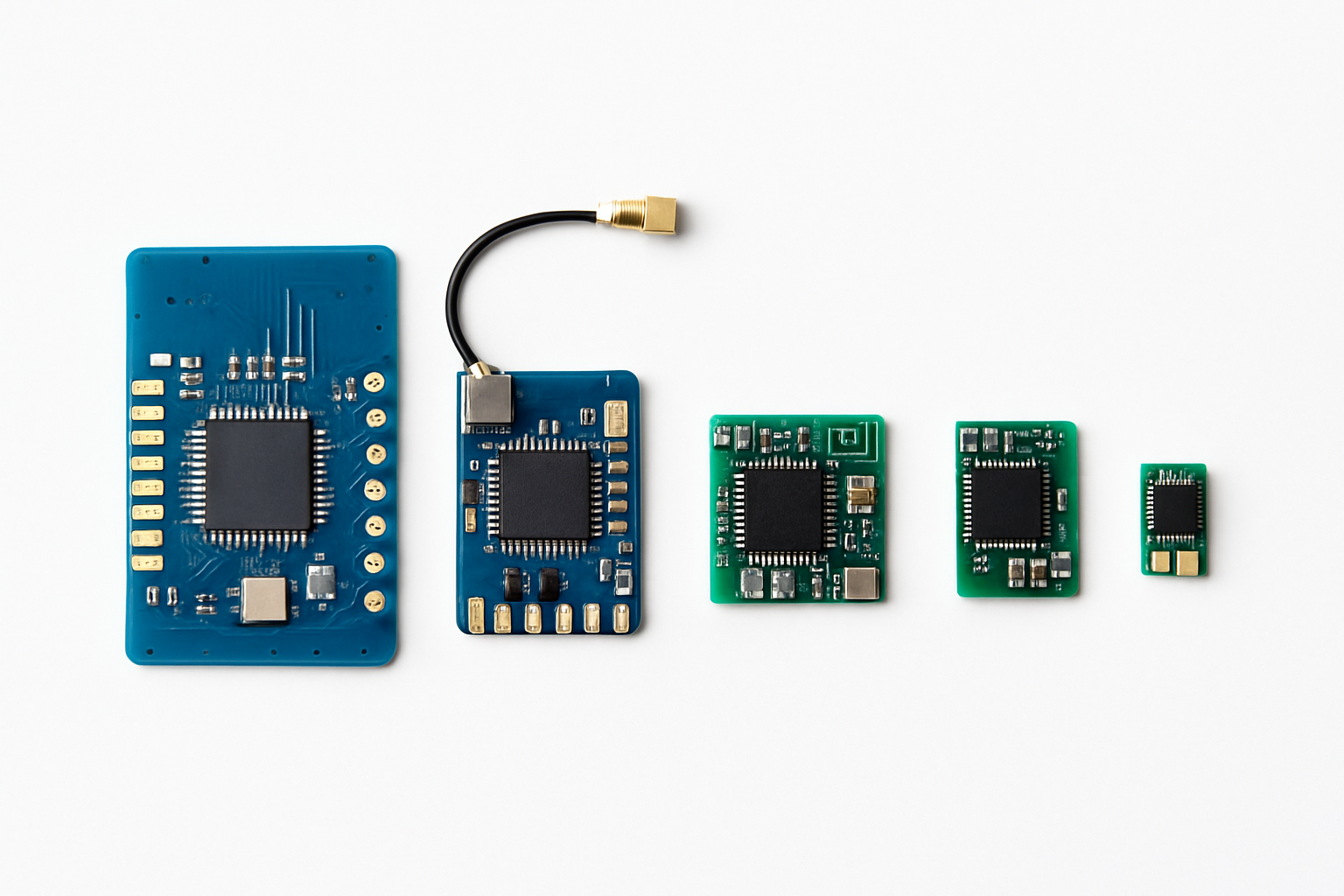

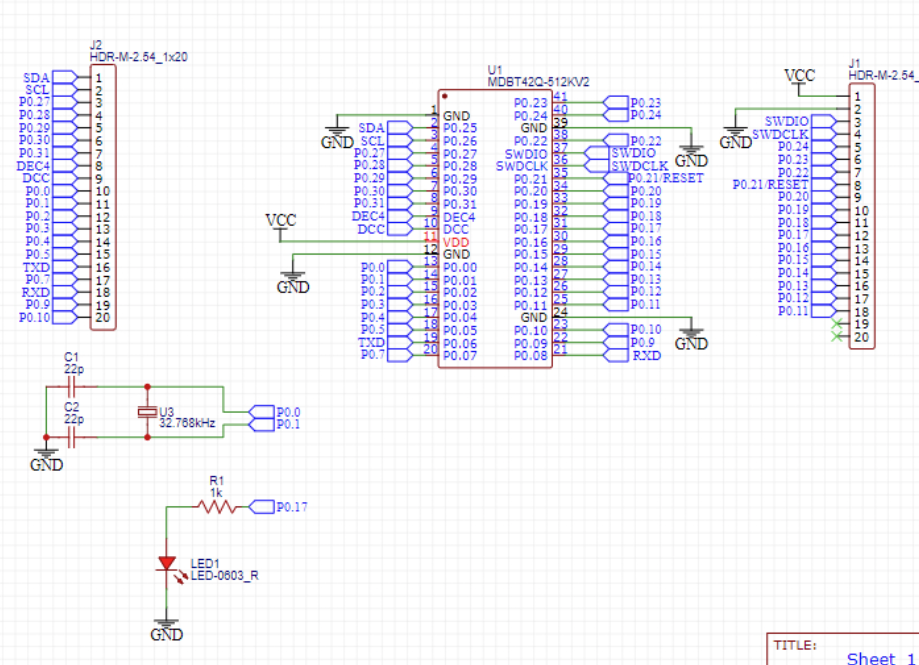

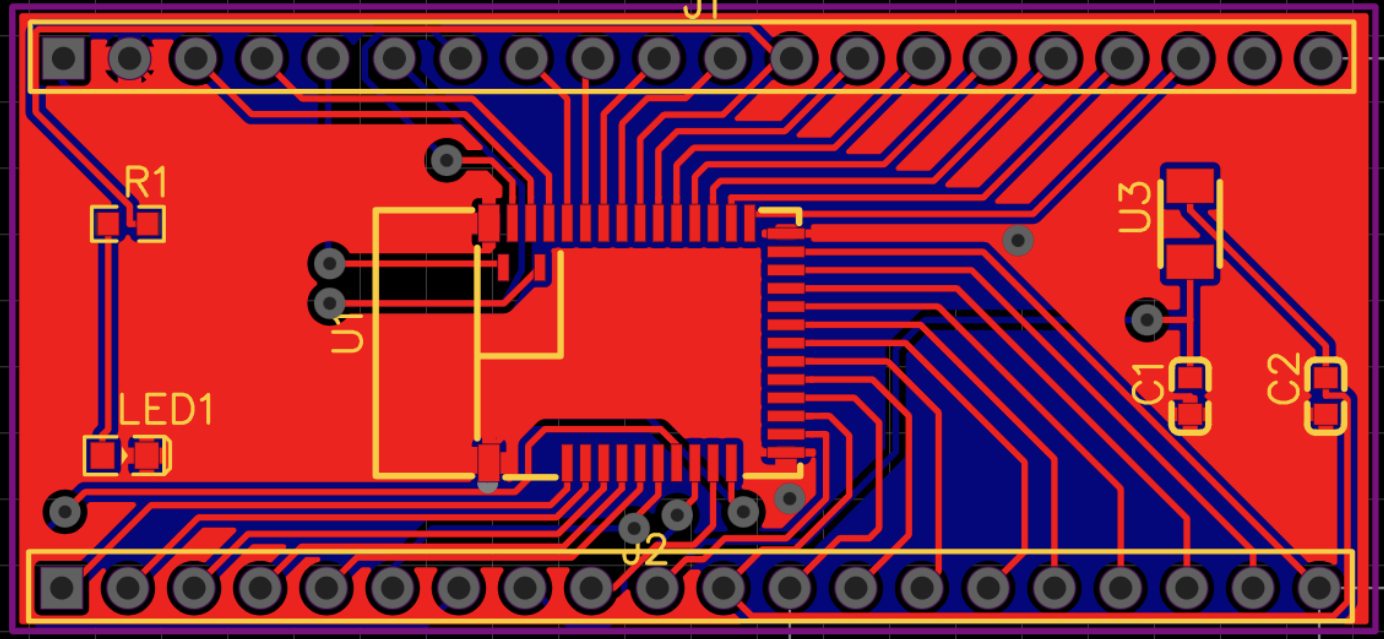

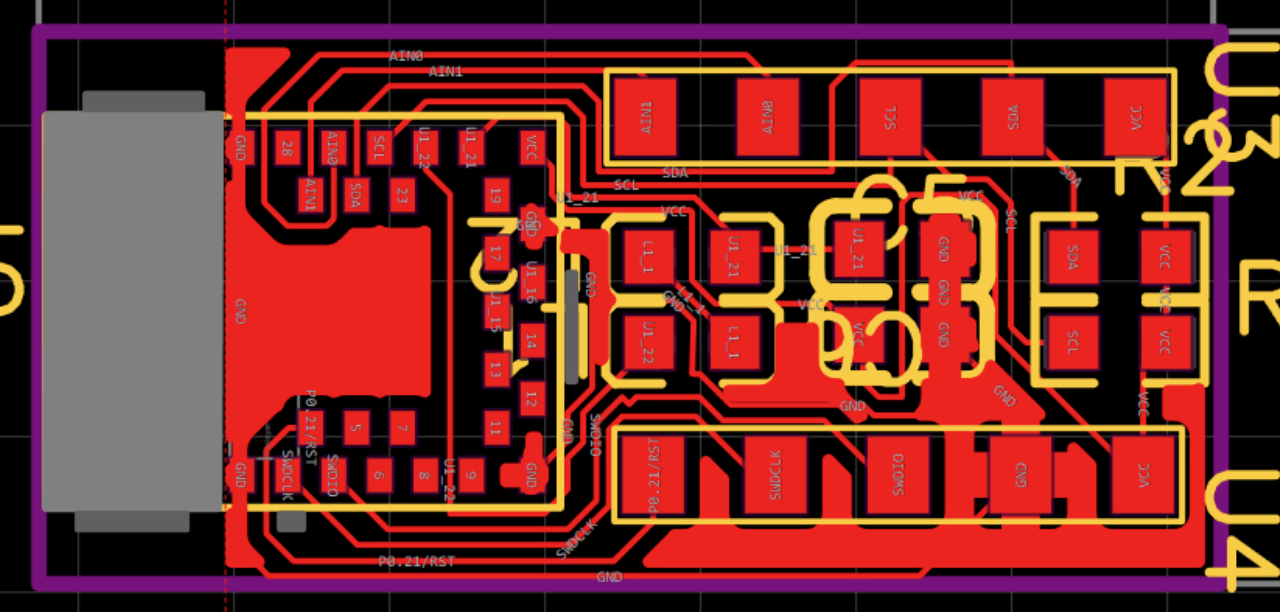

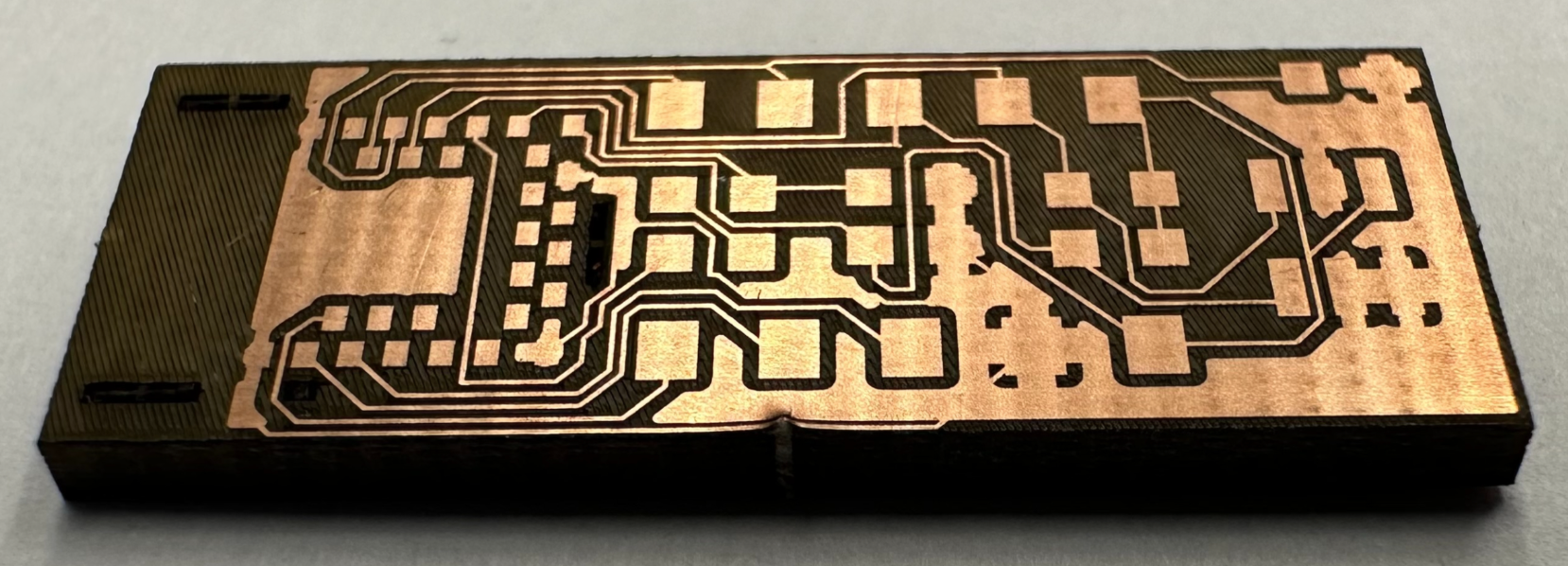

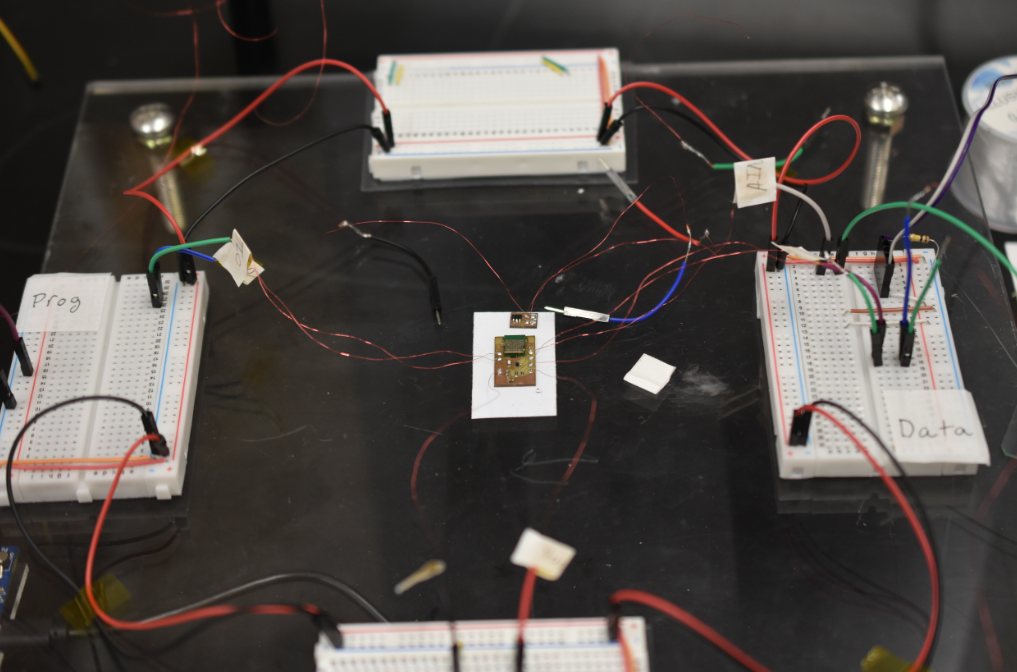

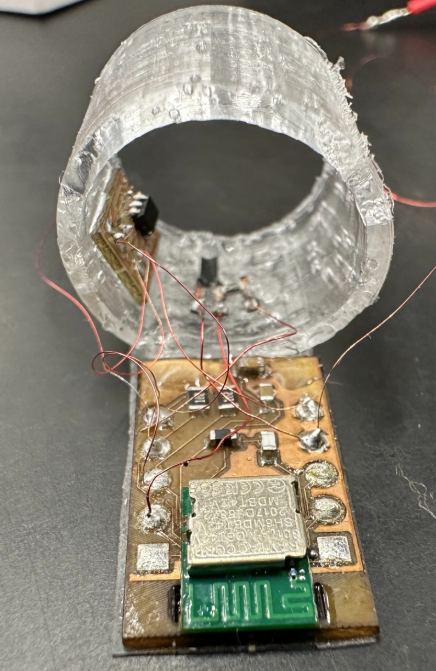

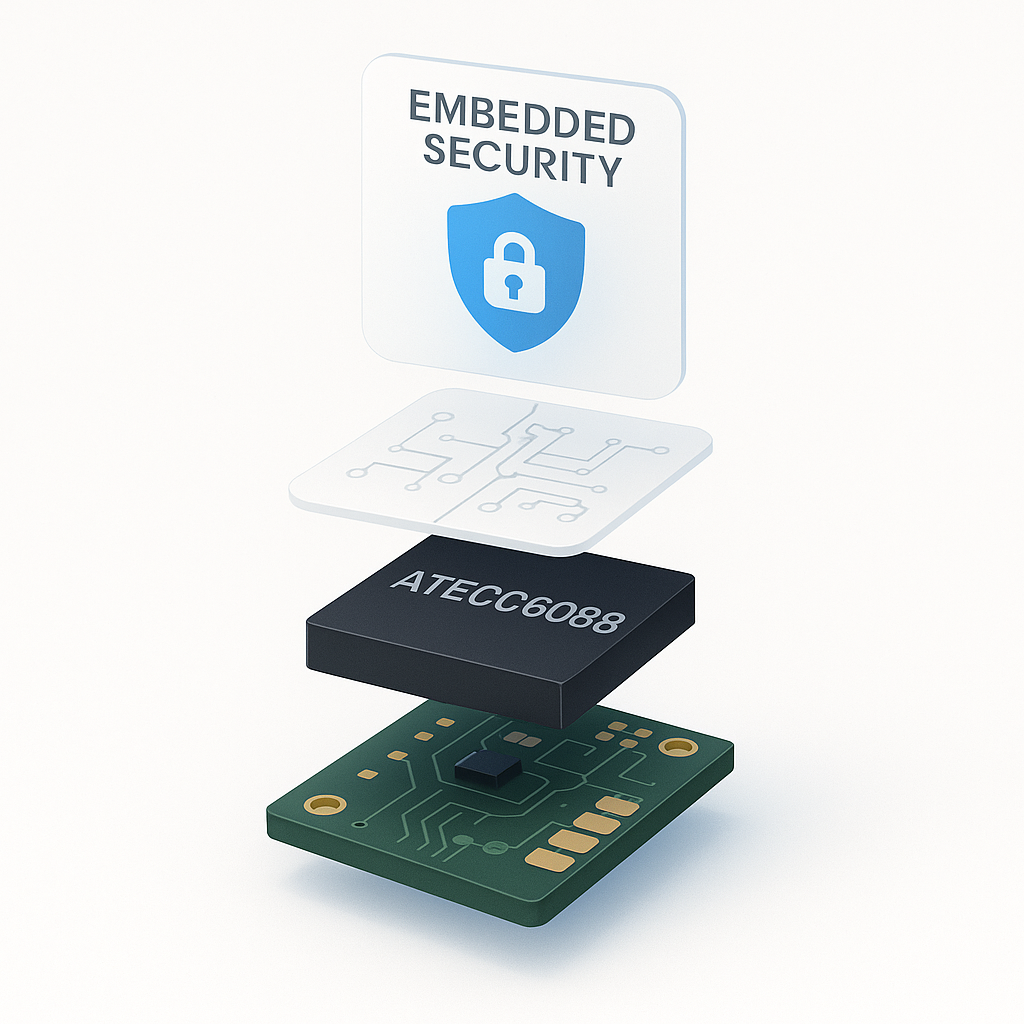

Hardware Security Dev

Firmware Engineering Project

2024

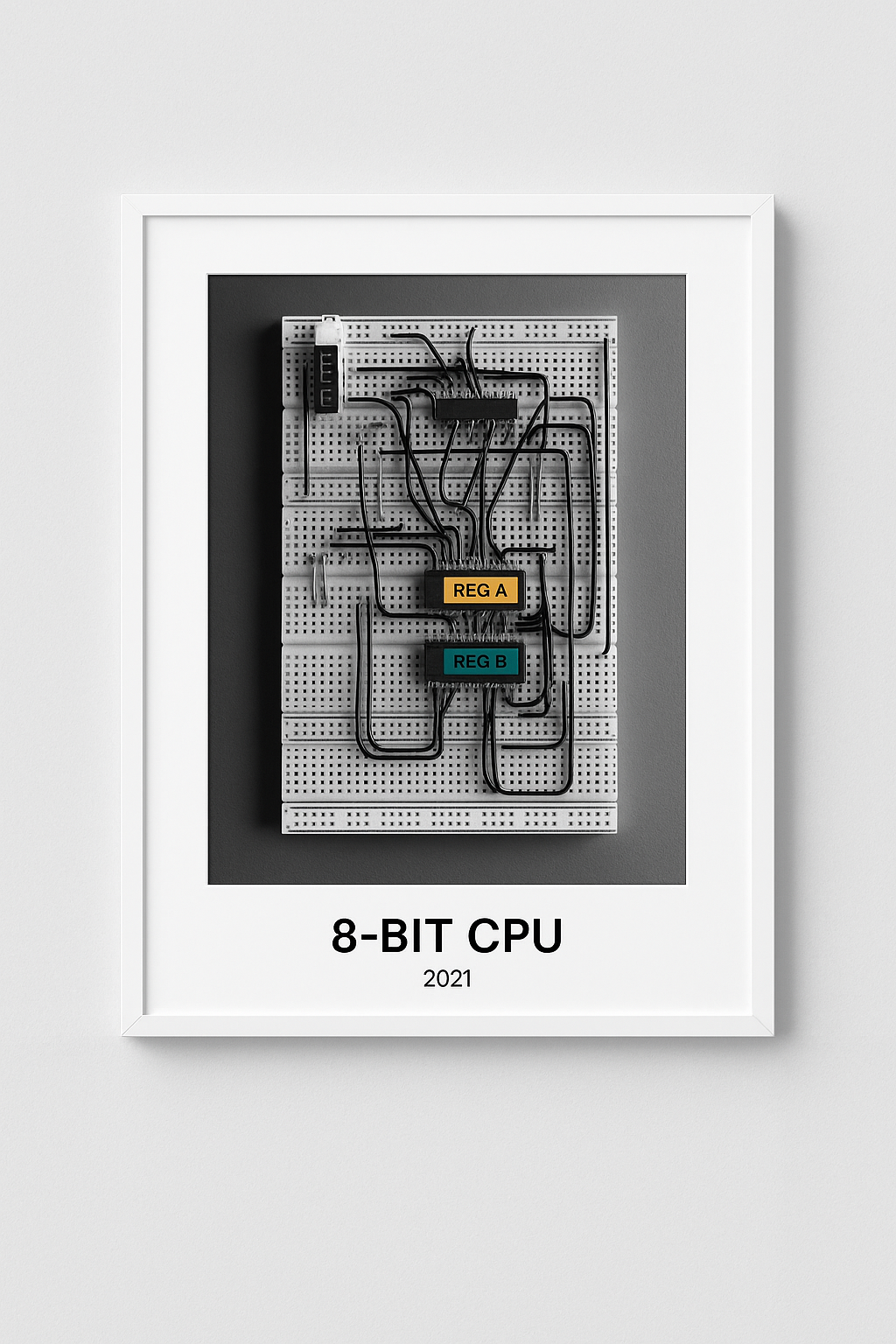

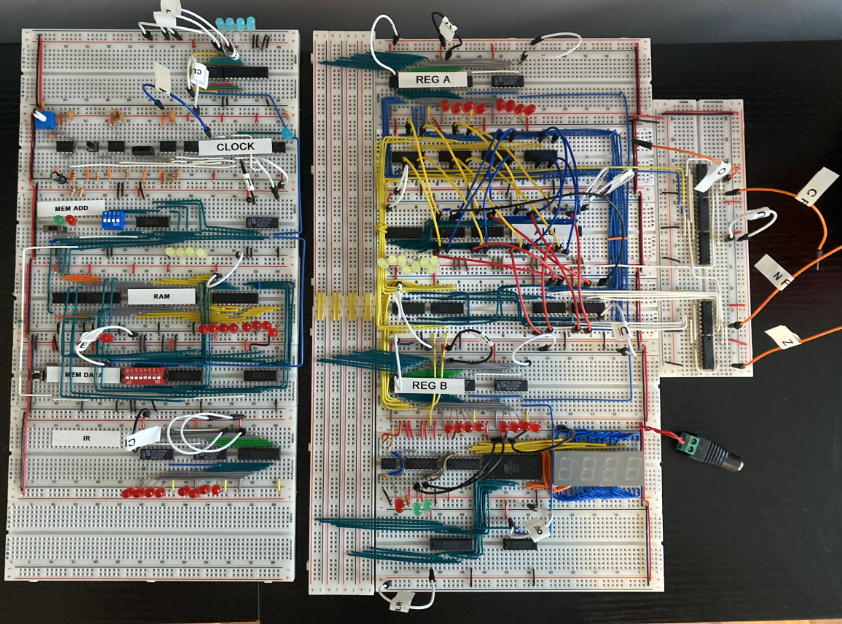

8-Bit CPU

Engineering Project

2022